Wall and Roof Panel Materials

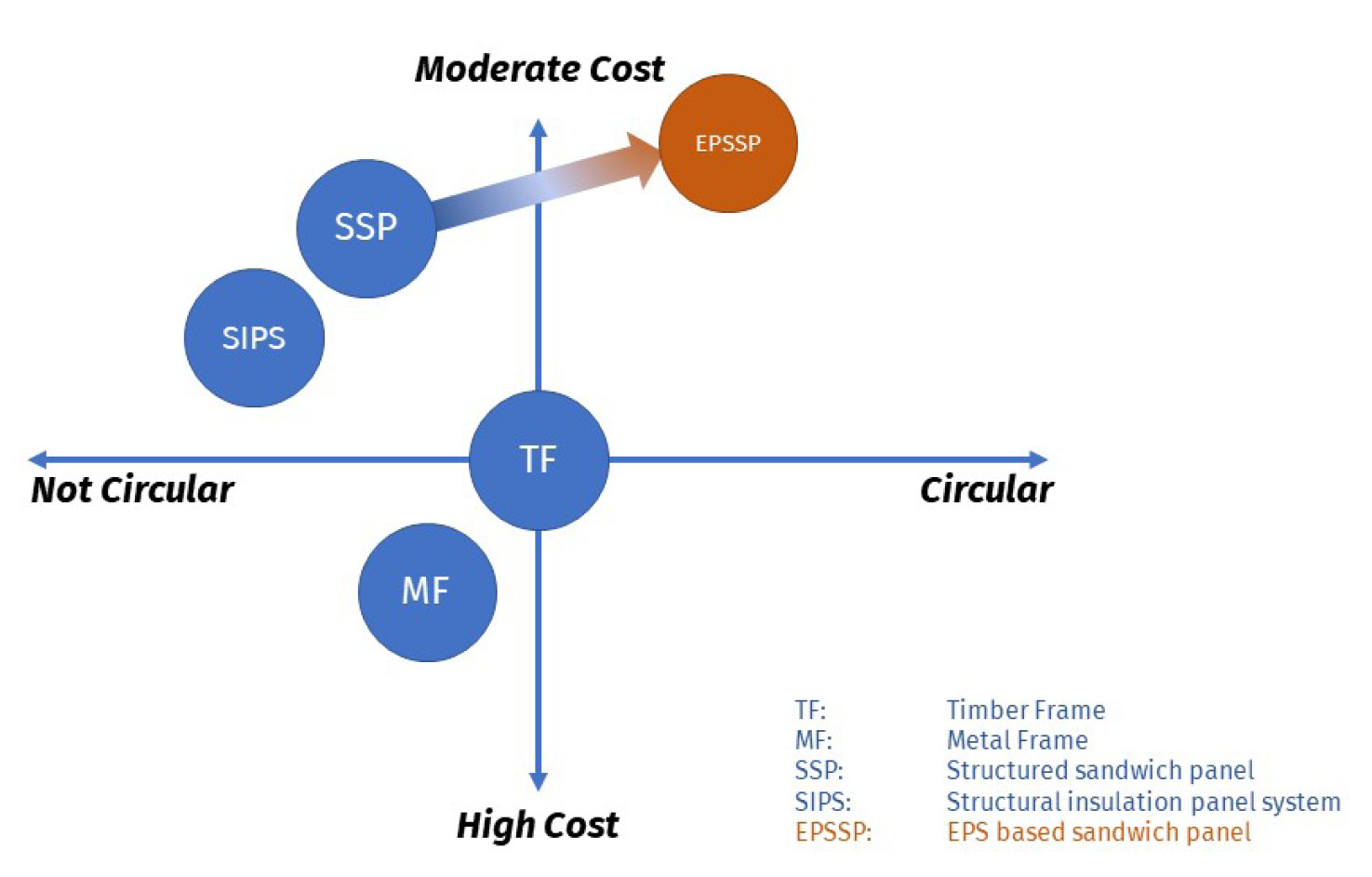

We aim to develop a sustainable and affordable product. The materials used for the panels have a significant impact on the environmental footprint of a house post-renovation. That is why we analysed, as part of the research, the properties of four types of available panels that are currently on the market: timber frame structure, metal frame structure, structured sandwich panel and structural insulation panel system.

The timber frame structure and sandwich panel were investigated further as they seemed to be the most promising for automation and cost reduction. The results showed that there was little difference in the environmental footprint between the sandwich panel and timber frame panel, but the sandwich panel scored best overall on the following points:

- Wall and roof construction using the sandwich panelling system need less materials which makes it easier to produce and recycle.

- The production of the sandwich panel is more suitable for automation which results in reduced production time and cost.

- The environmental impact of the sandwich panel equals the impact of the timber frame, according to an analysis over the whole life cycle from raw material to disposal. These results concluded that the sandwich panel was the panelling option that offered the most potential. The focus was then switched to designing a sandwich panel that met our objectives. The picture below shows the main objective for the design.

This brought us to a stage of designing a new type of formation of the panel: the INDU-ZERO Sandwich Panel, largely made up of expanded polystyrene (EPS), a grey foam on oil basis. In the future there are possibilities to decrease the environmental footprint, for example with a bio mass balance production concept or by developing biobased products. These options are still very expensive.

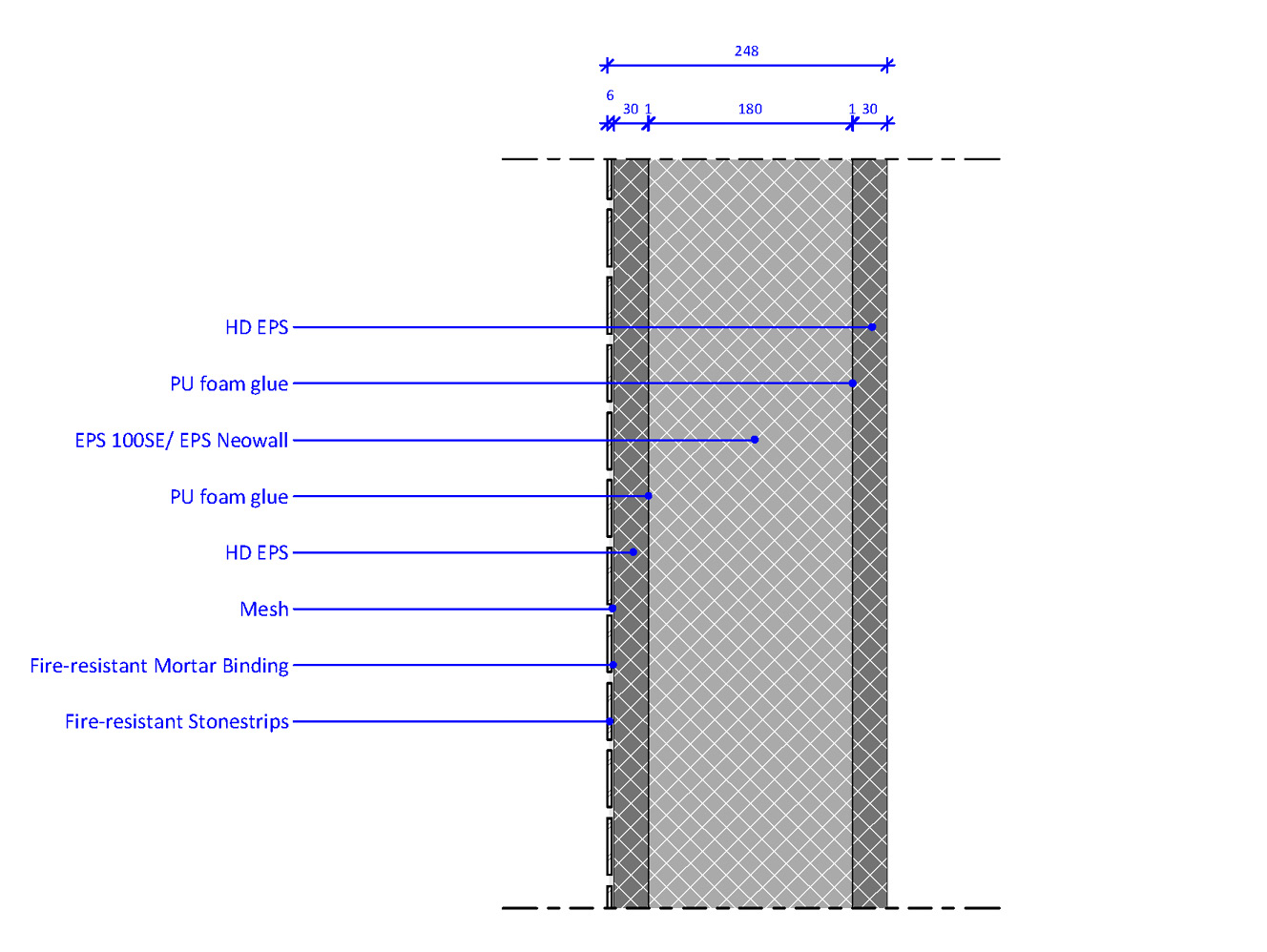

The figure below shows the build-up of the new INDU-ZERO Sandwich Panel. The outer core is made out of high-density EPS, the inner core of low-density EPS followed by the exterior finishing face which could be brick, render or timber look. The whole panel will meet fire class B (European Norm 13501), which is the highest class that can be achieved for this product. High-density EPS is a material that is easy to model and process in the factory with accurate tolerances, which makes it a great material for prefabricated purposes and installation on the building site. Within the INDU-ZERO project we have done small scale tests to check the feasibility of the concept. Official testing is still required, but is outside the scope of the INDU-ZERO project.